Winemaking solutions

Evitare l'ossidazione dei vini

Malolactic fermentation

Spontaneous malolactic fermentation is responsible for the production of biogenic amines and volatile phenols (Brettanomyces). What’s more, they carry a high risk of microbial faults, for example the production of off-flavours.

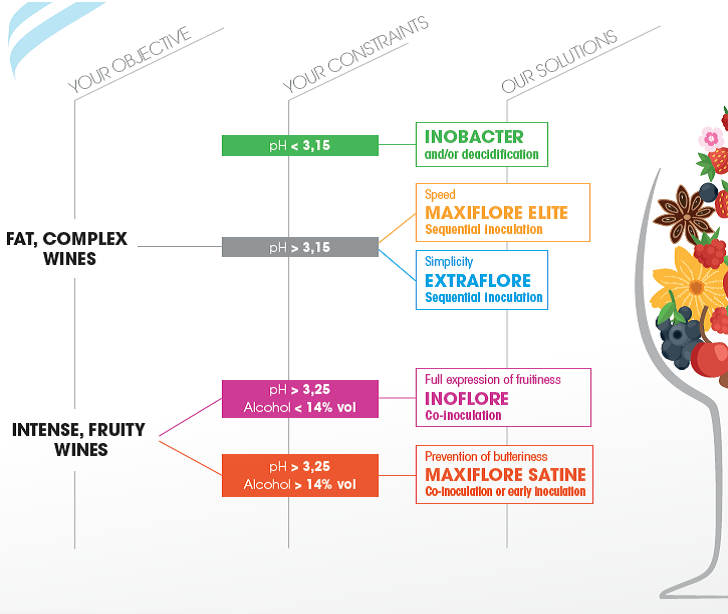

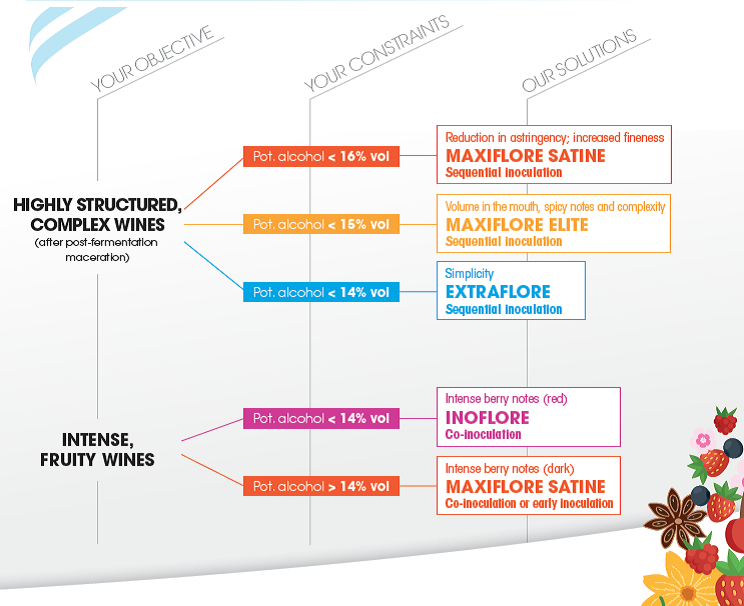

For optimal handling and control of the malolactic fermentation process, you need to use specially selected winemaking bacteria, inoculated in different ways (co-inoculation, early inoculation or sequential inoculation).

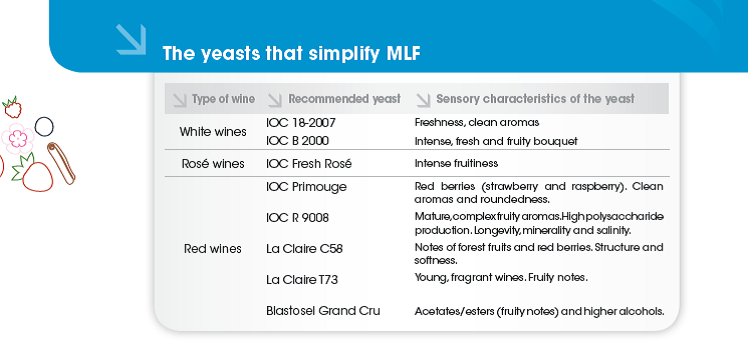

IN WHITES AND ROSÉS

IN RED WINES

Sometimes it happens that, under equal conditions, indigenous bacteria complete MLF more quickly than specific winemaking bacteria. The reason for this lies in the competition between the selected and the indigenous bacteria. In general, specially selected bacteria produce a smaller amount of diacetyl and ethyl lactate than indigenous bacteria do – these are the molecules responsible for creating notes of butter, milk, yogurt, off-flavours and more. Moreover, with these bacteria, volatile acidity levels will be more limited and the expression of fruity aromas will be more marked, as will sensations of freshness, complexity, creaminess and fullness in the mouth. At the same time, vegetal notes will recede.

The winemaking bacteria selected by Perdomini-IOC are incapable of producing biogenic amines or volatile phenols.

Therefore it’s evident that using specially selected bacteria enables you to handle malolactic fermentation more successfully, and attain a better sensory profile and safer wine for consumers.

The bacteria in the MAXIFLORE range in particular have been chosen for their ability to modify the sensory profiles of wines. MAXIFLORE SATINE acts mainly on esters – enhancing fruity notes in particular – while MAXIFLORE ELITE leads to a terpene-based aromatic profile (spicy and floral notes).

The following conditions facilitate optimal start-up and completion of malolactic fermentation:

- L-malic acid > 1.2 g/l;

- Good availability of nutrients;

- SO2: molecular < 0.3 – 0.5 mg/l – free < 10 mg/l – total < 60 mg/l;

- pH between 3.2 and 3.5;

When using sequential inoculation, NUTRIFLORE FML provides the right nutrition and survival factors to ensure that the bacteria multiply adequately (recommended dosage 20g/hl).

Perdomini-IOC provides technical support and laboratory analysis services which can help you select and successfully use the most suitable winemaking bacterium for each individual situation, and also establish protocols for use (malolactic fermentation feasibility tests, acidification, de-acidification, detoxification, blends, etc.)

Here are some hints to help make co-inoculation safer and more productive:

- Sulphuring on the grapes < 5-8 g/100kg

- Watch out for pH levels > 3.5. Above this number, Pediococcus and Lactobacillus strains work best. For musts with high total acidity levels and low pH, we recommend using IOC Inobacter.

- The bacteria must be inoculated 24-48 hours after the beginning of alcoholic fermentation.

- Make sure there is plenty of nutrition in the juice during alcoholic fermentation, so that bacteria and yeasts won’t have to enter into competition with each other. Organic nutrition is to be preferred. Bacteria cannot assimilate ammoniacal nitrogen.

- It is recommended to avoid alcoholic fermentation when:

- it starts off spontaneously;

- there are yeast strains which produce a lot of SO2;

- there are yeast strains with considerable nutritional requirements.

The yeast strains to combine with lactic bacteria in order to allow malolactic fermentation through co-inoculation must meet the following criteria:

- Moderate fermentation kinetics;

- Limited/low SO2 production;

- Medium-to-low nutritional requirements.

The usual method is to sulphur the must and use technological additives.

If, however, you wish to use a more natural method but still be sure you can govern the bacterial population, the answer is IOC Sentinel. This innovative solution is a totally allergen-free and OGM-free way to govern the bacteria before and after malolactic fermentation. IOC Sentinel is a new natural and vegan-friendly technological additive made from a blend of chitin-derived polysaccharides.

IOC Sentinel:

- Makes it possible to avoid MLF when it’s not wanted;

- Makes it possible to adequately conserve Charmat-method bases (where low SO2 levels are crucial in order to set off the bubble-formation process optimally);

- Is a very useful option for anyone who wants to work with low sulphur doses;

- Has bacteriostatic and bactericidal power on both Gram + and Gram – bacteria.

IOC Sentinel can also be used on red wines where MLF is already complete, as it:

- Stabilizes wines where MLF has taken place and avoids the classic forms of spoilage;

- Performs a clarifying/de-clouding action.

Nitrogen management

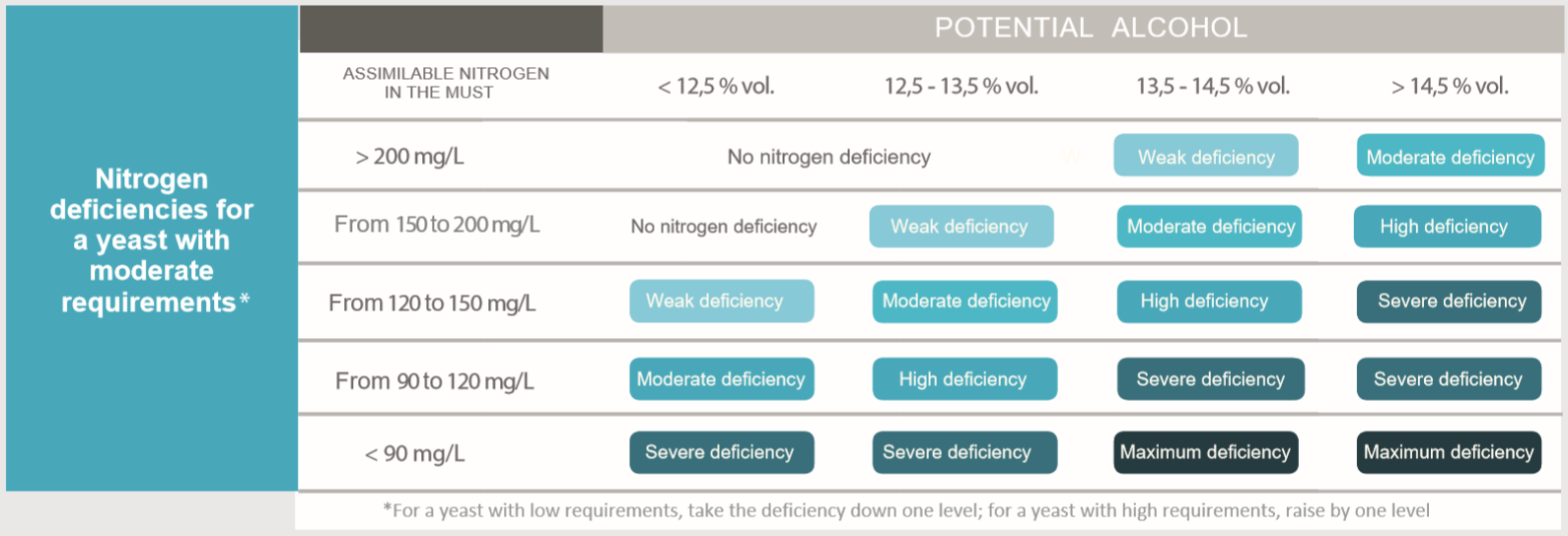

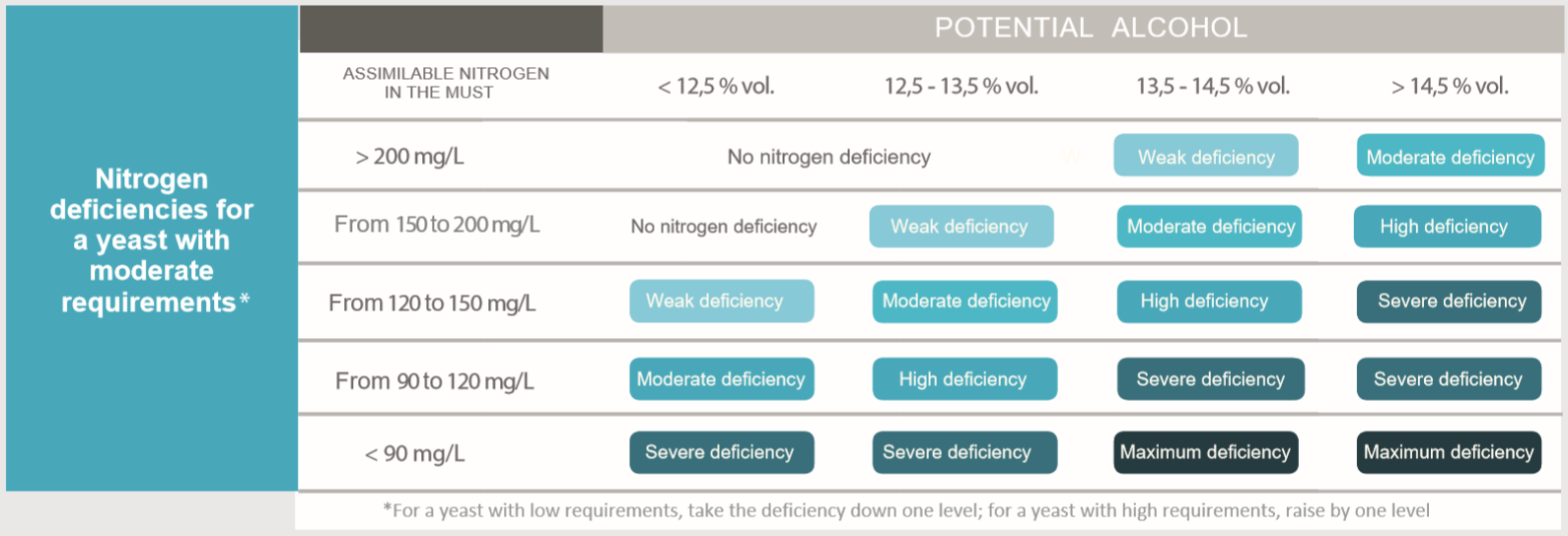

Yeasts with moderate nitrogen requirements need around 150mg/l of assimilable nitrogen in order to give a positive start to alcoholic fermentation (AF). However, this figure can be influenced by a number of factors, sugar concentration first and foremost. What’s more, some yeast strains have very modest requirements while others need a lot more. Using the table below, you can tell what level of deficiency you have based on the concentration of YAN in your must.

Other factors, such as low pH (<3,1) or “extreme” temperatures (<14°C or >28°C) can also slightly raise the need for nitrogen.

Nitrogen deficiency can manifest in various ways:

- Insufficient multiplication of the yeast for completion of AF;

- The yeast produces H2S, leading to sulphurous odours known as flattening;

- Not enough membrane proteins are produced to allow the sugars or the aromatic potential of the grapes to be adequately integrated by the yeast;

- Lack of amino acids (aroma precursors) meaning less expressive wines;

- Difficulties with malolactic fermentation because of the bacteria competing for the available amino acids.

Indirectly, the right kind and amount of nitrogen-based nutrition can limit the onset of other problems, whether of a microbial or sensory kind.

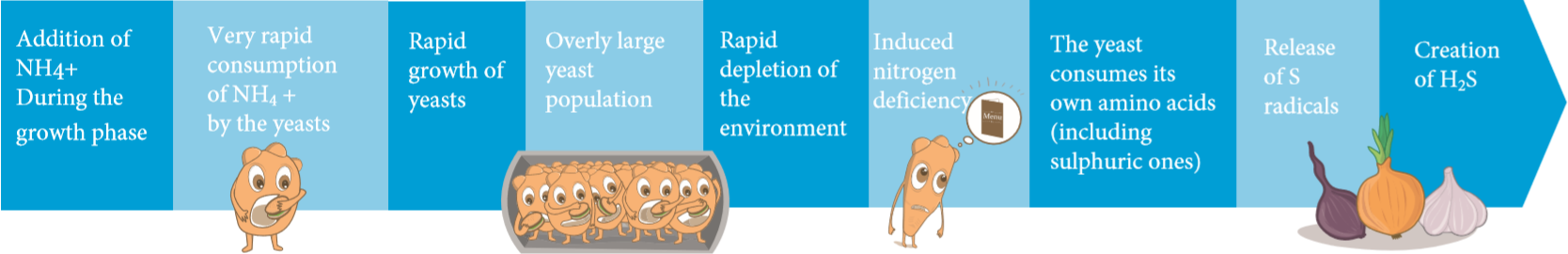

Although nitrogen deficiencies are dangerous, blindly adding nitrogen could create an excess which would be just as problematic. More specifically, an excessive amount of ammoniacal nitrogen during the growth stage (up to a third of the way through AF) will be assimilated too rapidly by the yeast, leading to an overly large population which will continue to use up the nitrogen-, vitamin- and mineral-rich nutrients in the must. The result is an induced deficiency leading to the production of undesirable sulphurous odours.

Nitrogen deficiencies and excesses both lead to problems, some of which can be serious, depending on the general conditions. This is why we always recommend analyzing YAN levels, as this allows you to provide the right amount of nitrogen and therefore proceed safely.

Lastly, we should always bear in mind that simply checking on the growth of the yeast isn’t enough. Protecting yeasts by providing them with sterols and polyunsaturated fatty acids increases their chance of survival and enhances their impact on the sensory characteristics of the wine. Ecobiol Pied de cuve Arom is a yeast protector with a wealth of selected sterols and survival factors for use in clarified musts and/or those with a high sugar content. It also optimizes the assimilation of aroma precursors through the yeast cell membrane.

When there is a YAN deficiency, yeasts use their own amino acids as a source of nitrogen; these include sulphides, which release sulphur ions into the wine and lead to the formation of undesired compounds that produce unpleasant odours. From a sensory point of view, the best type of nutrition to use is 100% aminic nitrogen, as it leads to the production of wines with more fruity thiols and positive aromas created by esters. Remember that a high ammoniacal nitrogen content inhibits the synthesis of certain aromas in yeasts, which, no longer needing to break down amino acids, form fewer secondary products (higher alcohols and their esters). Excess ammonium also has a negative effect on the penetration of varietal thiol precursors into the yeast, which can lead to wines lacking in fruity thiols.

Nevertheless, sensory problems can arise from other sources. Vitamins are organic compounds essential for helping yeasts to survive in stressful conditions. Vitamin deficiencies can lead to sudden changes in fermentation activity, and also to problems like unwanted odours and sulphurous compounds. Using nutrients such as ACTIVIT O/ACTIVIT AD brings about positive integration of nitrogen-based compounds and compounds rich in vitamins and minerals.

The first step is to find out how much nitrogen is in your must. To understand if there’s a deficiency and, if so, how serious it is, please read “When can we talk about nitrogen deficiency?“.

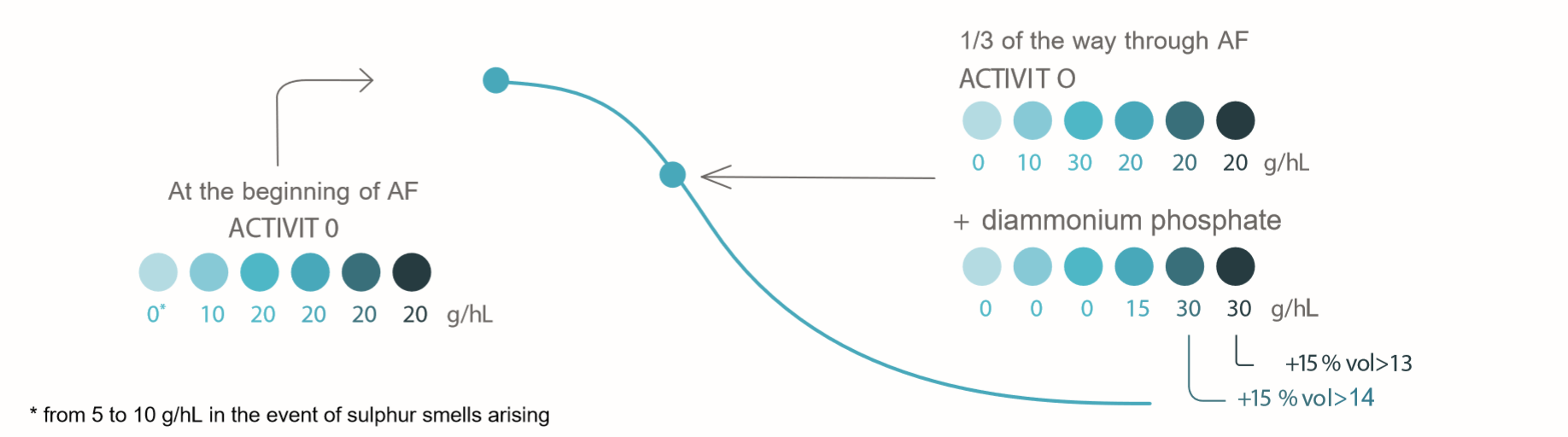

We recommend providing nutrition through ACTIVIT O, dosed according to the level of deficiency found.

Activit O is a yeast autolysate with extremely high assimilable-amino-acid and thiamine contents which can be used at any stage of alcoholic fermentation. It meets yeasts’ nutritional needs, helps winemakers achieve their sensory goals and also adheres to the winemaking philosophy that prevention is better than cure. What’s more, the micronutrients in ACTIVIT O (minerals, magnesium, zinc and potassium) play an essential role in yeast physiology, in particular cell multiplication and fermentative metabolism.

ACTIVIT is also suitable for use in organic wines.

To transform nitrogen into organic compounds, oxygen plays a vital role. It’s highly recommended to air the biomass each time nitrogen-based nutrition is added.

Nutrizione organica dei lieviti

Sparkling wine process with Traditional or Charmat Method

Re-fermentation is very similar to alcoholic fermentation. There are, however, a few differences. The base wine, with alcohol content of between 10% and 11% vol, low pH and low SO2 provides a more hostile environment compared to must. Re-fermentation takes place in sealed or autoclave bottles and not in open vats, such as in alcoholic fermentation.

The presence of CO2 and the pressure limit the growth of the yeast. Therefore, it is important to acclimatise the yeast, preparing a pied de cuve.

The pied de cuve begins with 1-2 millions of living cells per ml.

Yeast multiplication is greatly limited by a number of factors, which characterise the base wine. When these conditions are particularly difficult, we recommend increasing the amount of the pied de cuve to more than 3 million living cells per ml, to compensate for the absence of any cellular multiplication, and to avoid any difficulties at the end of re-fermentation. By following our protocol, with a quantity equivalent to 3-5% of the pied de cuve, you

will be able to obtain cellular concentration sufficient to complete the re-fermentation.

In addition to the degree of alcohol and pH value, you must also take into consideration the amount of SO2 present in the base wine or, more precisely, to the free SO2. Generally, wine is adequately protected with free SO2 levels of 10 mg/L, with the scarce inhibition of the yeast’s activities; once this threshold has been exceeded, there is the potential risk of inhibition

(to limit the use of potassium metabisulphite, see the use of IOC Sentinel*). Furthermore, even the temperature plays an important part. Re-fermentation is difficult to begin below 10°C, whilst if the temperature is above 20°C, there is a deposit that is difficult to remove because of the high number of yeast cells. Moreover, the initial CO2 levels in the base wine decanted may disturb re-fermentation. The initial pressure of 0.2 bar, corresponding to 0.4 g/L of CO2, shall lead to a reduction in the cellular growth of 40%, compared to a carbon free base wine. When the base wine’s conditions are in compliance with the limits of acceptability, but re-fermentation takes place with difficulty, you will have to keep every single factor or the combination of more than one factor

under control, which have a negative influence on the process. Other factors, such as pesticide residue, can have a negative effect on re-fermentation.

When it is added prior to tirage, Solution ST provides the sparkling wine with an abundance of structure.

Furthermore, the presence of copper sulphate helps to prevent the reduction defects that are common during the winemaking process. The causes of this kind of reduction are many, and the reduction defects are generally described in terms of sulphur, rubber, rotten eggs, etc. When these defects are found in the base wine, they can be corrected by using Netarom Extra prior to tirage.

The clarifying products added to the base wine are very important to obtaining a quality end product.

Perdomini-IOC recommends the use of Cristalline Plus or NoOx (10 – 50 g/hL) on the basis of the sparkling wine you wish to obtain.

Even the filtration process must necessarily be carried out carefully. For this reason, according to the sparkling wine you wish to obtain, the technical assistance provided by Perdomini-IOC or the agent for the territory are at your disposal to supply any information required to manage the process better.

In the case of sparkling wine that is obtained by using the Charmat method, Perdomini-IOC recommend the use of NoOx (5 – 10 g/hL) in order to improve the refinement, bubble persistence, and increase its shelf-life.

Stuck fermentation

Usually, it’s not just one factor which leads to stuck fermentation, but rather a combination of different sub-optimal conditions for the yeast. On top of the classic monitoring of temperature, oxygen and turbidity, we also recommend that you watch out for:

- High sugar concentrations. In this event, you will need to use a yeast with strong alcohol production, resistance to osmotic stress and fructophilic tendencies, such as La Claire eXtreme (alcohol production > 17.5% vol.);

- During the yeast rehydration stage, it’s a good idea to use a protector such as Ecobiol Pied de Cuve AROM.

- Nitrogen-based nutrition. If there’s an initial deficiency in the must, it’s always better to use organic nutrition because it ensures that the growth of the yeasts will be smooth and regular. What’s more, too much NH4+ could be assimilated too quickly, with resultant overgrowth. Lastly, organic nitrogen is the only source of nitrogen which bacteria can also assimilate. We recommend using Activit O, backed up by the addition of DAP in the event of major deficiencies;

There’s a clear relationship between the optimal YAN value and potential alcohol.

- The presence of natural inhibitors. Yeasts themselves produce medium-chain fatty acids which accumulate on the yeast cell wall and become toxic. Try using Cellclean – Saccharomyces Cerevisiae yeast hulls – to detoxify the juice and limit the risk of sluggish fermentation. It’s also effective at removing any residues of plant medicines applied in the vineyard.

Even at this early stage, it’s important to provide the micronutrients which enable fungal growth. The role of sterols in ensuring optimal plasma-membrane function has been clearly demonstrated. Low concentrations of ergosterol act as a trigger for cell growth, while greater concentrations provide support for growth and the formation of intact membranes. In general, sterols are also incorporated inside the membranes as free sterols and act as structural elements. Using Ecobiol Pied de Cuve Arom is a guarantee of inoculation in a “fresh” biomass, i.e. a biomass which can multiply by adapting to the growing difficulties of the vehicle. What’s more, the micronutrients produced optimize the development of the sensory effects of the fermentation and help the yeast to compete with the indigenous microbial flora.

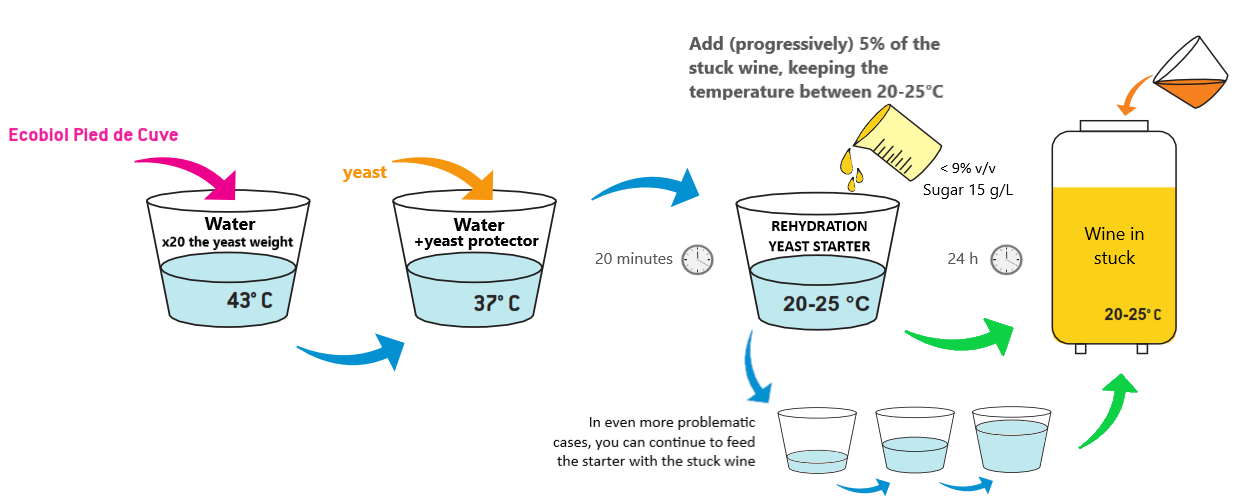

When there has been no drop in density in the last 24-48 hours, we can say that fermentation has become stuck. In this case, it will be necessary to add active yeasts to the alcoholic mass without adding more sugar.

We recommend that you:

- Use Cellclean (30 g/hl) to detoxify the must of inhibitors and add a small amount of sulphur (1-2 g/hl);

- Wait for sedimentation to occur, then transfer the juice to separate it from the spent lees. Rack if there is grape marc in the juice;

Prepare a starter for inoculating active dry yeasts (30 g/hl). You will need to use yeasts suitable for stuck fermentation, such as IOC 18/2007, La Claire SP665 or La Claire Extreme.

Prepare a starter for inoculating active dry yeasts (30 g/hl). You will need to use yeasts suitable for stuck fermentation, such as IOC 18/2007, La Claire SP665 or La Claire Extreme.

It’s important that the alcohol level of the stuck wine used for the starter does not exceed 9% vol. and contains 15g/l of sugar. This is crucial in order to avoid the yeast being immediately subjected to osmotic stress and to allow it to adapt to the fermentation environment gradually;

Make sure that the difference in temperature between the starter and the must does not exceed 10°C;

- When almost all the sugar has been consumed (approx 2-3 g/l), inoculate the vat. In even more problematic cases, you can continue to feed the starter with the stuck wine, even several times, and keep monitoring the sugar consumption. Work at a controlled temperature between 20-25°C.

Other techniques for restarting stuck fermentation could include adding marc from a vat where fermentation is proceeding well, using the lees from a vat where fermentation has recently reached completion or adding freshly crushed grapes.

This is a generic protocol. For information about your specific case, contact our technical support team.

When density is below 1.005, and it decreases by just one or two thousandths a day, it’s likely that the fermentation will grind to a halt. The best thing to do is to investigate the possible causes of the slowdown.

If all the usual parameters (temperature, nitrogen, sulphur dioxide, pH, etc.) are within normal ranges, consider adding Cellclean to remove any inhibitory compounds produced by the yeast during fermentation. Cellclean is also effective at removing any residues of plant medicines applied in the vineyard. Re-inoculation can be performed using a strongly fructophilic and osmotolerant yeast (e.g. LaClaire SP665- Extreme) in order to add active biomass to the juice.

Adding oxygen is probably one of the most effective ways to govern fermentation. Yeasts need oxygen to produce sterols and unsaturated fatty acids endogenously; these compounds are vital for carrying sugar inside the cell. Even with white wines, it’s crucial to air the fermenting must: yeasts and CO2 stripping have a great ability to absorb oxygen, thus protecting the aromas from oxidation. When airing is done right, it’s not dangerous and leads to an increase in fermentation activity. A quantity of around 5-8 mg/l added in one go will result in smooth, complete fermentation (the exact quantity varies depending on the characteristics of the must – the more oxygen is needed the higher the sugar concentration and level of cleanness are). The ideal time to administer oxygen is at the end of the yeast’s growth stage, which generally coincides with the moment when around ¼ of the total sugar has been consumed, or halfway through fermentation if nitrogen-based nutrition has been added. Remember that the more viable the yeasts, the more they need nitrogen compounds. Nitrogen-based nutrition should be provided through organic nutrients (Activit O), or a nutrient complex like Activit AD/Activit/Ecobiol.