In winemaking, flotation is a process which separates solid particles from the liquid environment of must. These particles migrate to the surface of the tank, forming a “lees cap”. Flotation is carried out before alcoholic fermentation, therefore is a preparatory stage in which the must is fined and stabilized before inoculation with selected yeasts.

Flotation can be a very useful way of reducing the risk of the wine developing sensory deviations, as it limits the contact of the must with the oxidizable molecules responsible for off-flavours.

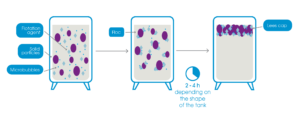

This procedure has become widely used by winemakers, in particular when crafting white and rosé wines. The process works by forming hydrophobic flocs through the interaction of the solid particles with targeted fining agents added for the purpose of increasing the density of the particles. With denser solid particles, when a gas (nitrogen or compressed air) is added they can be effectively separated from the liquid environment. The flocs rise up to the surface and condense into a compact foam (lees cap). The interaction between the gas and the flocs takes place at a pressure of 5-6 bar for a short time.

The speed at which flotation can be performed is calculated using a mathematical formula. The formula tells us that the greater the size of each particle to separate from the liquid, the faster the procedure can be performed, which is why strategies need to be put in place to increase the size of the particles.

Flotation is a procedure that needs to be completed quickly, straight after harvesting, and needs the grapes to be healthy if it’s to be successful.

In order to use this technique effectively, it’s also crucial to use targeted pectolytic enzymes (Zimopec Flottoflash, Zimopec 2Flottoflash) to reduce the viscosity of the must and therefore allow the particles to rise up to the surface more easily. Depectinizing the must is a vital part of the flotation process, which is why we highly recommend carrying out a “pectin test” to ensure that the pectins have been fully hydrolyzed before proceeding with flotation.

Starting from left:

- Negative test: the pectin has been totally hydrolized

- Slightly positive, medium pectin level

- Positive test: medium-to-high pectin levels, formation of agglomerates of varying weights

The temperature of the must when the flotation procedure is carried out is just as important as depectinization, as it also affects the viscosity of the must – when performed at 15-20°C, the must has a viscosity that allows flotation to be carried out effectively and the spontaneous onset of fermentation can be avoided.

Targeted formulas in ready-to-use, vegan-friendly solutions

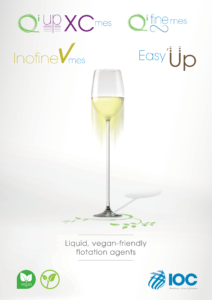

In order to contribute actively to the swift migration of the particles to the surface and significantly increase the efficacy of the flotation procedure, IOC has developed a range of highly innovative products. Our liquid flotation agents have been developed to meet two of the main requirements of wineries: to have products at hand that can be used immediately, leading to savings in terms of time, and to have the option of using products free from ingredients of animal origin and/or approved for use in organic winemaking.

Thanks to their affinity to the colloids needing to be separated, the main function of flotation agents is to increase the density of these particles so that they can rise up more easily. They also play an important role in stabilizing the must and protecting it from oxidation.

Our fungal-origin chitosan formulas (from “Aspergillus Niger”) have some very useful, innovative properties as regards oxidative processes, such as their ability to combat free radicals. Chitosan is also able to trap “transition metals” such as iron and copper, which act as oxidation catalysts.

- Qi Up XC Mes: activated vegetable chitosan

- Qi Fine Mes : activated pea protein and vegetable chitosan

- Inofine V Mes : activated pea protein

- Easy’Up : activated pea protein, charcoal and bentonite clay

Other agents that help fine the must and create a compact lees cap are bentonite clay (Bent’Up) and activated charcoal (Carbo F). Flotation is the ideal solution for a winemaker who wishes to use charcoal, as long as the charcoal is always used in tandem with bentonite clay to remove every trace of residue.

After the required enzyme treatments and having carried out a pectin test, it’s advisable to carry out a test on a pilot scale in order to select the most effective flotation agent before proceeding on an industrial scale.

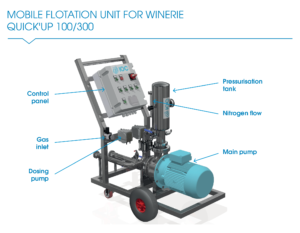

Quick’Up (100/300) flotation units

Quick’Up units are easy-to-use flotation systems for use when the must is circulated continuously in a single tank, with the addition of a flotation agent to encourage the formation of flocs, and a flotation gas. These units generally use an agent that is progressively added as the must circulates by small, on-board peristaltic dosing pumps. Two different sizes of unit are available, so that each winery can choose the size that best meets their needs: Quick’Up 100 (100 hL/h at 5 bar) and Quick’Up 300 (300 hL/h at 5 bar). Thanks to the Quick’Up flotation units supplied by IOC, even small volumes of must can be floated.

Conclusion

Flotation is a rapid process suitable for use on white and rosé must and can be implemented in a variety of different situations, if the right tools are available.

There are several advantages to carrying out a flotation procedure:

- swiftness of the process: just 2-4 hours;

- greater microbiological safety, thanks to the swiftness of the process;

- energy saving: temperature between 13-20°C (no need to cool the must);

- tank management: no need for extra tanks, as those already in place in the winery can be used;

- less solids to treat: time saved.

The availability of targeted, ready-to-use flotation agents free from animal-origin proteins provides the winemaker with some innovative and highly effective tools.